Application example:

System solutions

for inline fluid processing

Problem:

How do I get a complete system solution rather than having to integrate all of the components myself? Will it be CE marked and certified for pressure, etc.?

Solution:

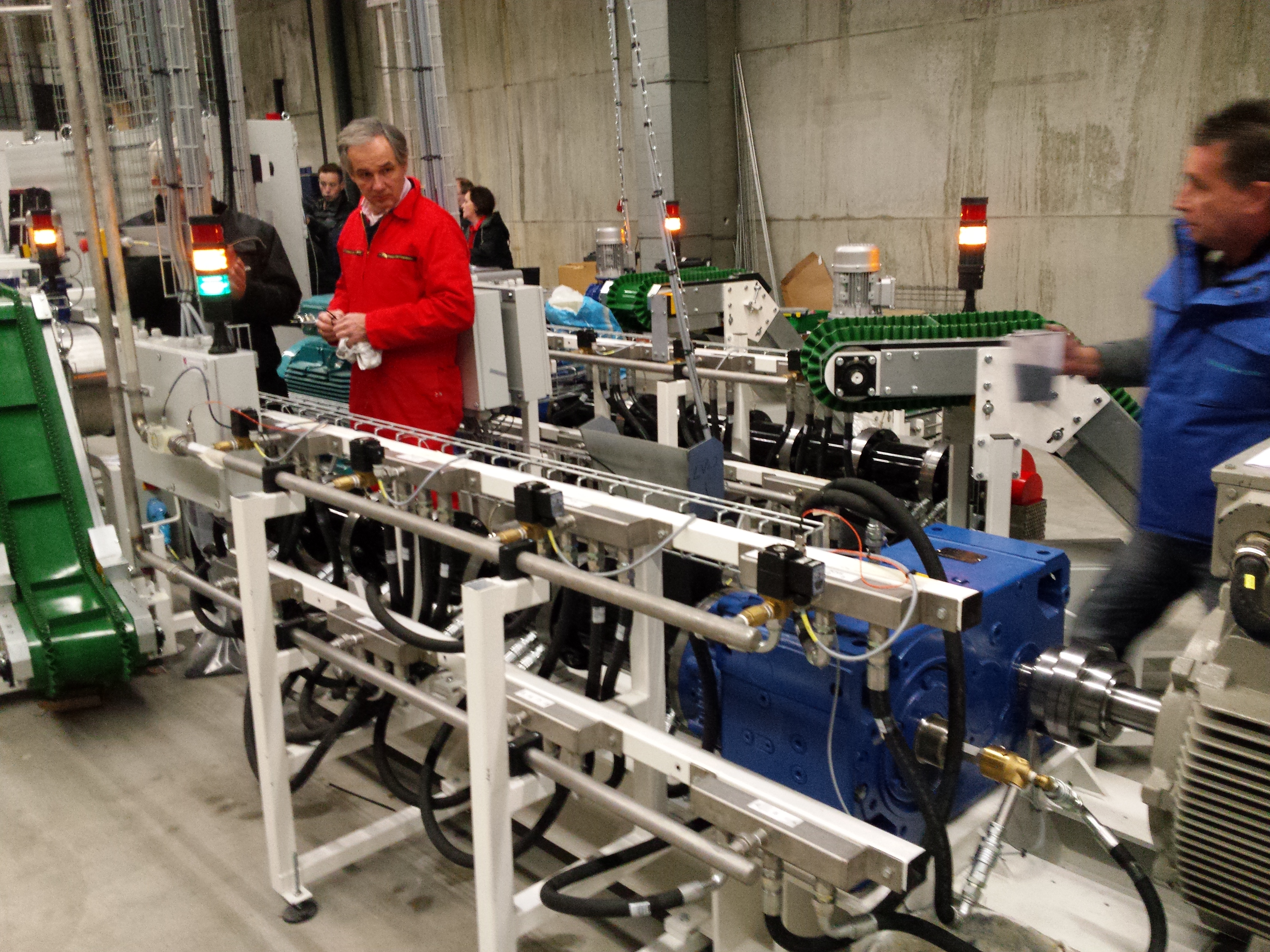

An integrated dosing, pumping and mixing system from Maelstrom with drives, controls, software and full documentation and certification package.

Application example:

System solutions

for inline fluid processing

Problem:

How do I get a complete system solution rather than having to integrate all of the components myself? Will it be CE marked and certified for pressure, etc.?

Solution:

An integrated dosing, pumping and mixing system from Maelstrom with drives, controls, software and full documentation and certification package.

Mixing is at the heart of most fluid processing applications and the increased drive towards process intensification using inline solutions is making the design and building of systems ever more complex. Without detailed knowledge and experience of particular mixers, the difficulties of sizing and selecting suitable components can also be daunting. Add to this the requirements of CE marking, national standards, pressure regulations, etc. and the system budget can rapidly escalate. For those responsible for mixing operations, the problem is: how can can a complete system from ingredient addition through to packaging be sourced from just one supplier and can they deliver an integrate a complete, certified and documented package?

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.

With over 20 years' experience in supplying mixing-related equipment and systems, Maelstrom is trusted by some of the world's largest companies to deliver end-to-end process solutions for mixed fluid products. From simple "pump and mixer" skids through to complete production lines with multiple ingredient feeds and extensive instrumentation, the same quality control and design procedures are used to deliver dependable, solutions at a fixed price and on time.

The documentation and certification package is a key part of any Maelstrom supply and this is where experience and detailed knowledge really counts. The relevant safety, hygiene and other standards must be considered in the design process from the start to ensure that the final system meets all of these criteria and that costly and time-consuming re-works are avoided.

Before any design work is started, Maelstrom's engineering team works closely with the customer to refine the specification and ensure that acceptance criteria can be tested and met. Draft designs are then provided for review and approval before build commences and routine build inspections are allowed to check progress. Factory and then site acceptance tests follow delivery of the system for completion of the project and handover to the customer's production team. Training is provided to customer personnel, as required, for safe and efficient system operation and maintenance. Finally, ongoing maintenance, support and spares contracts are available to ensure that the system continues to perform to specification and that any deviations are managed efficiently.

Maelstrom is pleased to be able to offer third party equipment integration so that customers get exactly the system they want. Whilst Maelstrom's unique range of mixers caters for a wide range of applications and materials, customers needing specific third party solutions will often require alternative mixers, pumps and other system components to be integrated into a system. Maelstrom has a strong track record of such integration projects.