Application example:

Colour blending

in continuous acetate film lines

Problem:

How do I blend liquid colour into acetate dope upstream of a film sheeting die to obtain consistent colour across the sheet?

Solution:

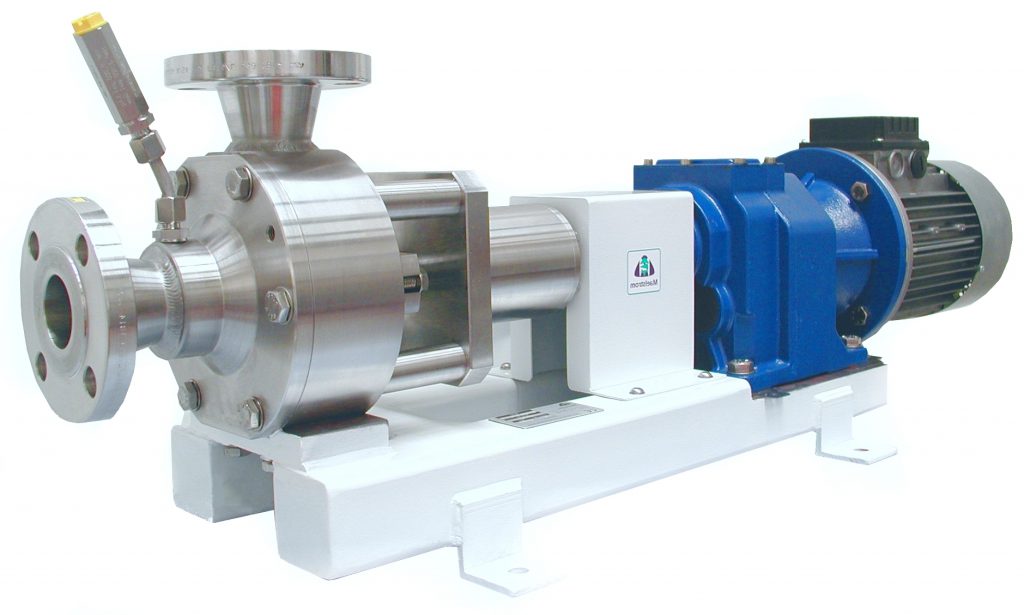

A DCL inline blending mixer from Maelstrom with direct injection dosing

Application example:

Colour blending

in continuous acetate film lines

Problem:

How to blend liquid colour into acetate dope upstream of a film sheeting die to obtain consistent colour across the sheet?

Solution:

A DCL inline blending mixer from Maelstrom with direct injection dosing

Blending concentrated liquid colour streams into a continuous film dope line places high demands on mixing consistency and overall performance. With traditional static and pin mixers, some streaking of colour is often seen in the final film and for many applications, such as packaging films, this is not acceptable. A high shear mixer is not appropriate as it can reduce the film quality and introduce heat. Any solution must not only provide high performance but must also be reliable, as any unscheduled downtime of a sheeting line is a major cost.

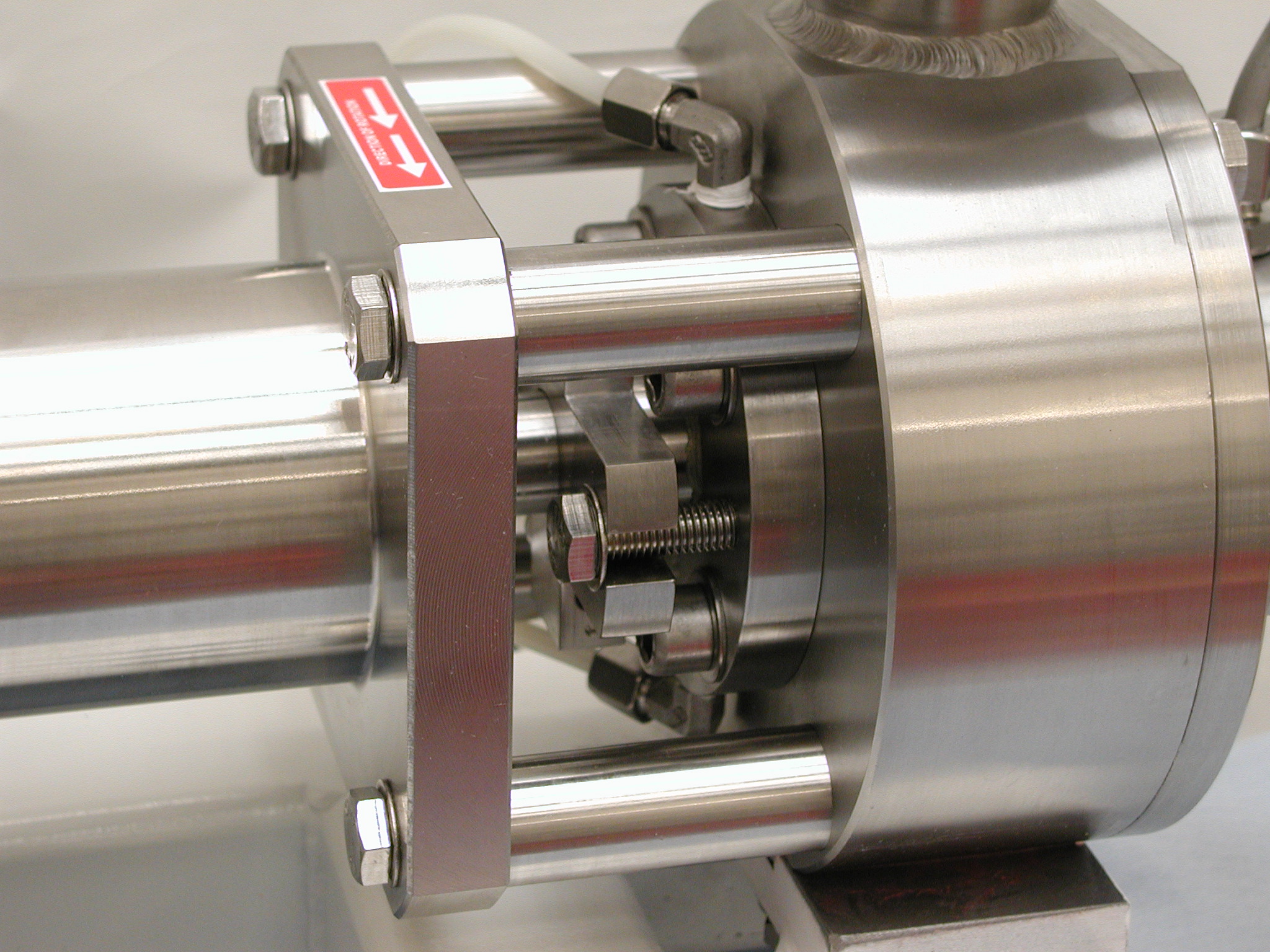

A DCL inline blending mixer is ideal for any application demanding high blending performance with minimal shear. The ability to dose additive streams directly into the mixing head minimises cleaning and the mixer can be linked to clean-in-place (CIP) systems for automatic flushing. For hazardous area applications, ATEX-rated motors, seals and bearings can be specified and hygienic options are also available where cleanliness is required.

Typically operating at low rotations speeds (hundreds of rpm) via a gearbox, DCL mixers are design for robust, long-term operations in tough environments where long maintenance intervals are the norm. Correct selection and design of piping and mixer positioning minimises product wastage in startup, shutdown and colour changeover operations.

The key advantages of the DCL over traditional static and pin mixers in this application are:

- Greatly improved blending performance - no streaks in the final film

- Simple cleaning and self-flushing when integrated with CIP

- Faster startup to achieve on-spec operation - minimises wastage

- Low back-pressure when compared to static mixers - primary stream and additives lines are easier, and usually cheaper, to pump

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.