UMH high speed

ultra mixer

Key Features

UMH high speed

ultra mixer

Key Features

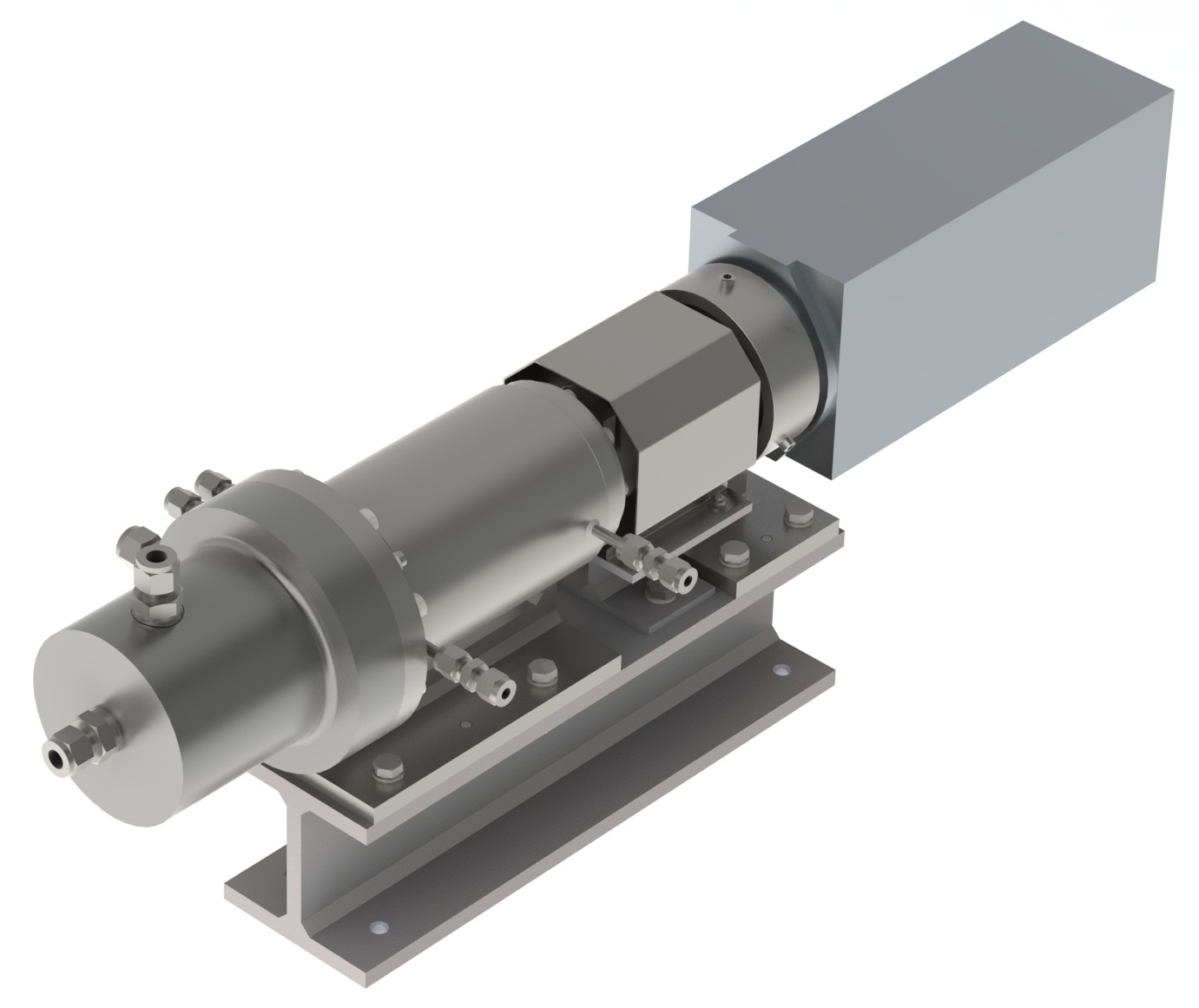

Rotating at speeds typically between 15,000 rpm and 60,000 rpm with pressure drops of 200 bar and higher, UMH inline mixers deliver high pressure homogenizer and ultrasonic mixer performance at higher flowrates and lower costs.

Designed for industrial production of solids dispersions and emulsions, the UMH is aimed at volume processing of sub-micron particles and droplets. With hygienic and flameproof options, the UMH can be used across a wide range of applications with fluid viscosities up to 1,000,000 cP.

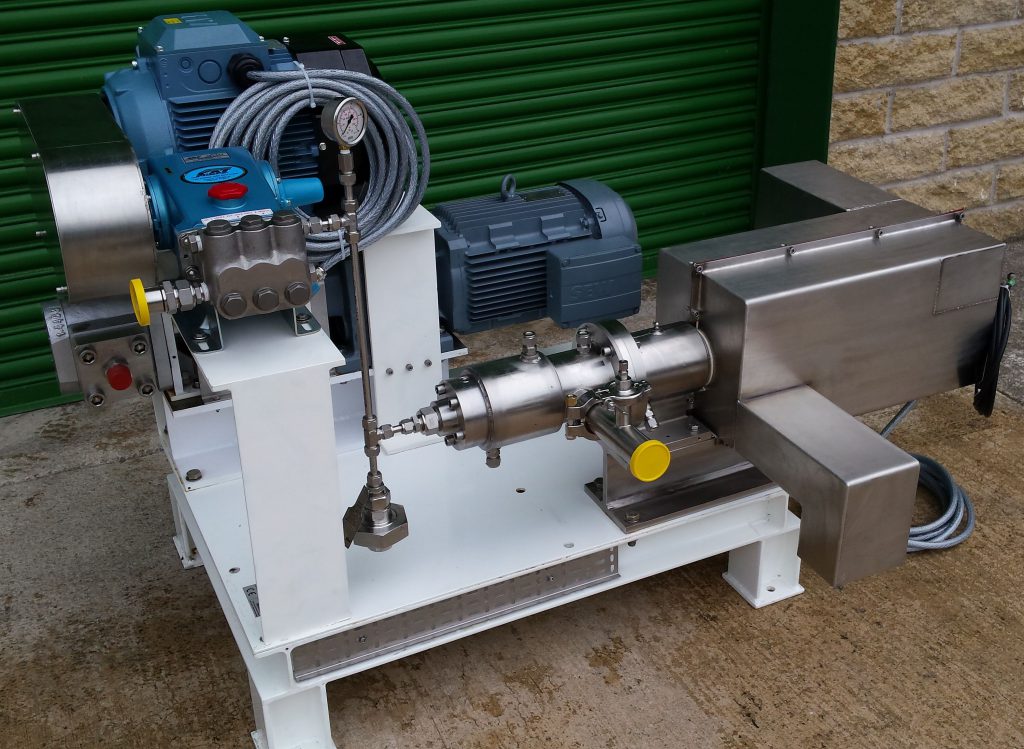

Generally supplied as a system skid, together with a high pressure feed pump, the UMH is easy to maintain and occupies a small footprint, making it an easy retrofit into existing installations where a performance boost is needed.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.

As the UMH mixer incorporates a multi-stage nozzle homogenisation action, the pressure drop across the mixer is normally high. However, when combined with the rotational shearing action, pressures are much lower than those in conventional high pressure homogenisers when achieving the same results. Maelstrom normally supplies UMH mixers paired to suitable high pressure pumps and dosing units as skid-based systems, together with drives and controls.

UMH mixers are high-end mixers for demanding dispersion and emulsification applications in the sub-micron range. Using a rotor-stator geometry with inter-cavity transfer features together with multiple nozzle zones, these machines provide extensional and rotational shearing and blending actions for ultimate performance.

Typical rotation speeds of 15,000 to 60,000 rpm are achieved using synchronous machine tool spindle drives which allow rotor-stator gaps to be reduced below 20 microns with reliable performance.

Aimed at production scale applications where high pressure homogenizers and sonication systems might be used, UMH offers a lower cost solution with a number of advantages in flexibility, viscosity range and the ability to blend and dilute.

UMH25

Max. flow up to 1,000 cP

2000 l/hr

Max speed: 60000 rpm

Motor power: 7.5kW

UMH50

Max. flow up to 1,000 cP

4000 l/hr

Max speed: 30000 rpm

Motor power: 30kW

UMH75

Max. flow up to 1,000 cP

10000 l/hr

Max speed: 20000 rpm

Motor power: 70kW

UMH100

Max. flow up to 1,000 cP

24000 l/hr

Max speed: 15000 rpm

Motor power: 110kW