Application example:

Solids Dispersion

general purpose high shear mixing

Problem:

How can I disperse and deagglomerate solids in liquids within a continuous, inline operation?

Solution:

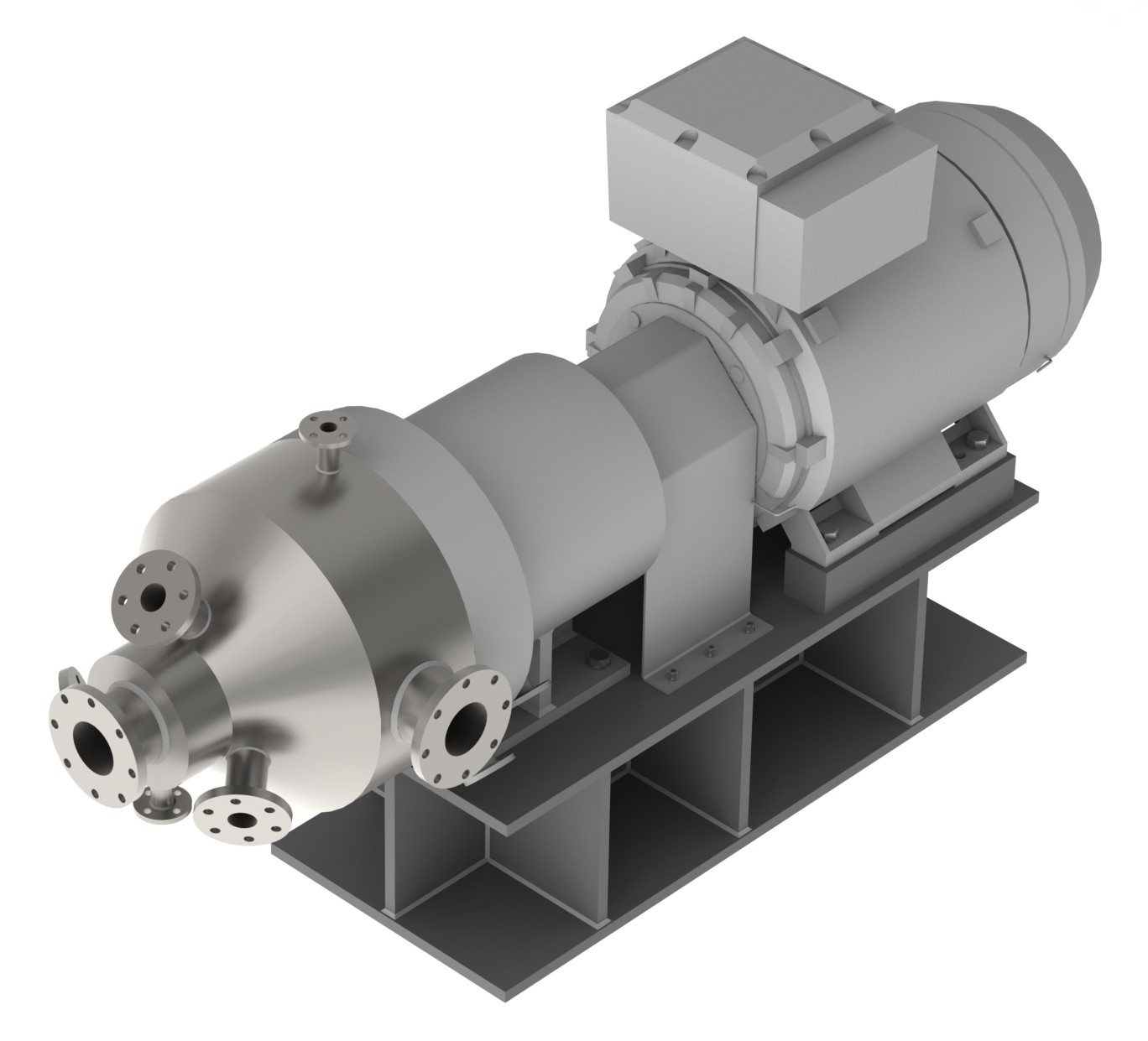

A DCH high shear mixer from Maelstrom

Application example:

Solids Dispersion

general purpose high shear mixing

Problem:

How can I disperse and deagglomerate solids in liquids within a continuous, inline operation?

Solution:

A DCH high shear mixer from Maelstrom

The dispersion of powdered and granular solids into liquids is one of the commonest mixing applications. A high shear mixer can be used to mix a roughly-blended slurry into a fine dispersion at high flowrates by wetting out and de-agglomerating the solids. Standard types of high shear mixers used for this task rely on rotor-stator mixing heads with very tight running clearances. This makes them prone to wear and damage from the product and a considerable amount of the fluid does not see the high shear mixing zone at all. Multiple passes through the mixer or multiple mixing stages are the only ways they can try to solve this.

A Maelstrom DCM high shear inline mixer is the ideal solution to the problem of powder dispersion and deagglomeration. Based on Maelstrom's patented FDM rotor-stator geometry with inter-cavity transfer action, the DCM is unlike any other high shear mixer. With its intensive hydraulic shearing action it can deliver at least 20% more energy to the fluid for the same motor size, meaning improved performance and more efficient operations. For deagglomeration results in the 1-5 micron mean diameter range, the DCM is also highly scaleable, with machines from laboratory scale through to 100 tonnes/hour and higher.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.