EPS extruder pump

single screw

Key Features

EPS extruder pump

single screw

Key Features

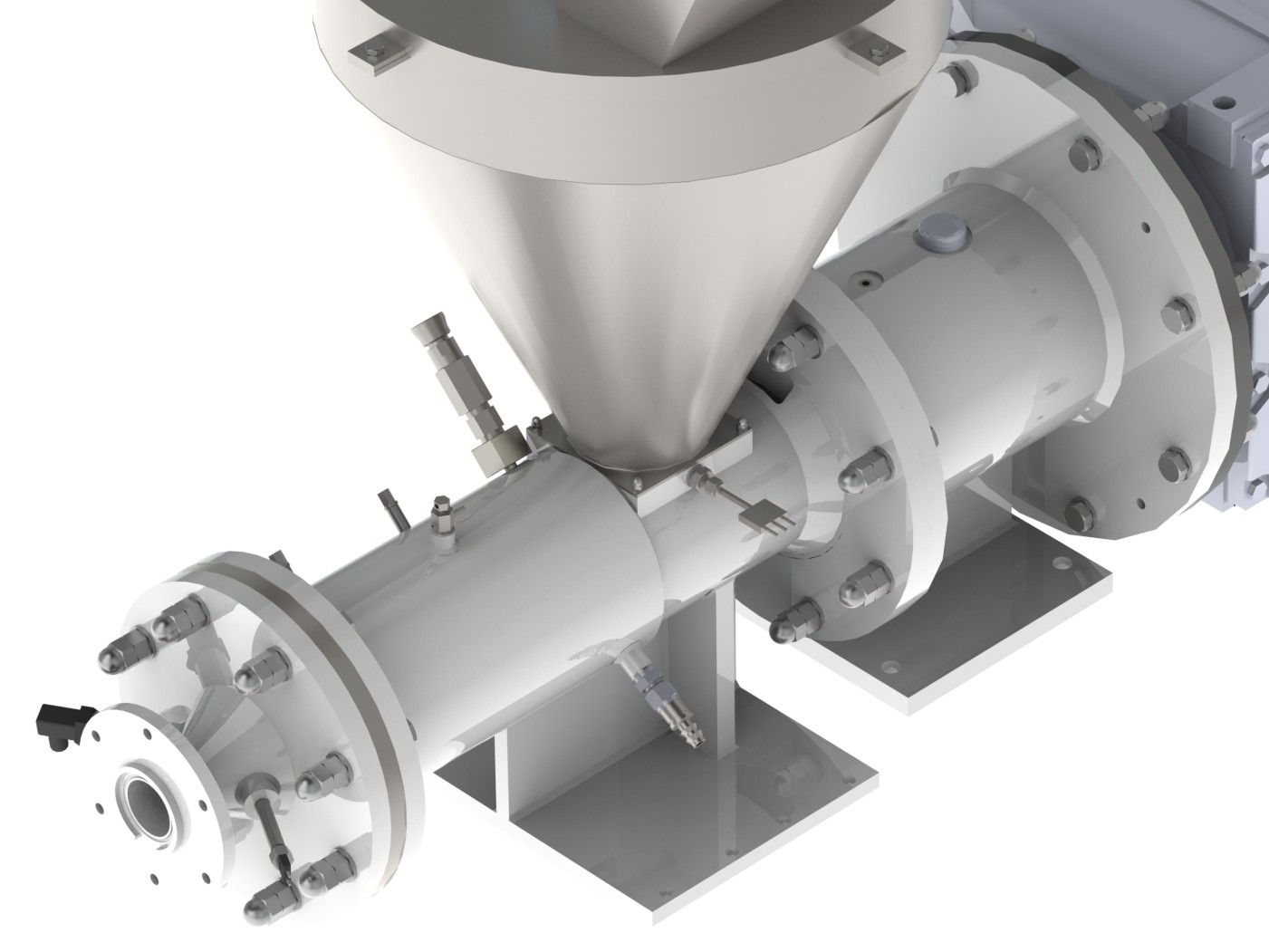

The EPS is based on decades of Maelstrom's extruder design expertise and uses state-of-the-art single screw extruder design to deliver an efficient, reliable, pulsation-free pump for viscous materials. EPS pumps can be fitted with optimised barrels for increased pressures, where required, and the screw and barrel can be liquid-heated or cooled. Electric heating can also be provided for higher temperatures.

As a simple and flexible pump for viscous fluids, the single screw extruder is often overlooked. With decades of development in the design of optimised screw and barrel combinations, Maelstrom has refined the single screw extruder into an effective and efficient pump for many high viscosity applications, especially for higher pressures (a traditional weakness of single screw extruders). Custom screw geometries can be fitted to suit individual applications or different processing conditions and extruders can also be made to meet EHEDG and 3A hygiene requirements.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.

Using a specially-designed sprung output flange, the EPS can provide integrated pressure relief to eliminate the risk of system over-pressure. For many high viscosity pumps, pressure relief is a major concern because conventional pressure relief valves can easily clog and jam. Maelstrom's design integrates sprung pressure relief directly into the flange so that it cannot clog and can also be easily cleaned and inspected after activation. Contact Maelstrom for more details.

The EPS is a single screw extruder that is optimised for high viscosity fluid pumping. Variable screw geometry for feed, compression and metering zones provides excellent material control and liquid-cooling or heating of the screw and barrel are possible, for thermal regulation. Using a carefully-designed barrel, the EPS is able deliver viscous pastes, polymers and doughs at pressures up to 500 bar with pulseless flow.

Designed for easy disassembly and cleaning the EPS can be used in food and pharmaceutical applications and flameproof options are available for use in hazardous environments.

EPS25

Max. flowrate

50 kg/hr

Max speed: 250 rpm

Motor power: 0.25kW

EPS40

Max. flowrate

250 kg/hr

Max speed: 250 rpm

Motor power: 0.75kW

EPS65

Max. flowrate

1000 kg/hr

Max speed: 250 rpm

Motor power: 3kW

EPS110

Max. flowrate

5000 kg/hr

Max speed: 250 rpm

Motor power: 15kW