Fluid mixers and inline mixing systems

Maelstrom is a leading supplier of high performance fluid mixing, blending and dosing equipment for inline process intensification. Based in the UK's North West region, we have been supplying advanced mixing solutions to some of the world's largest process companies for over 20 years.

Find out how we can help you to solve

your inline mixing process problems today.

INLINE POWDER-LIQUID BLENDING

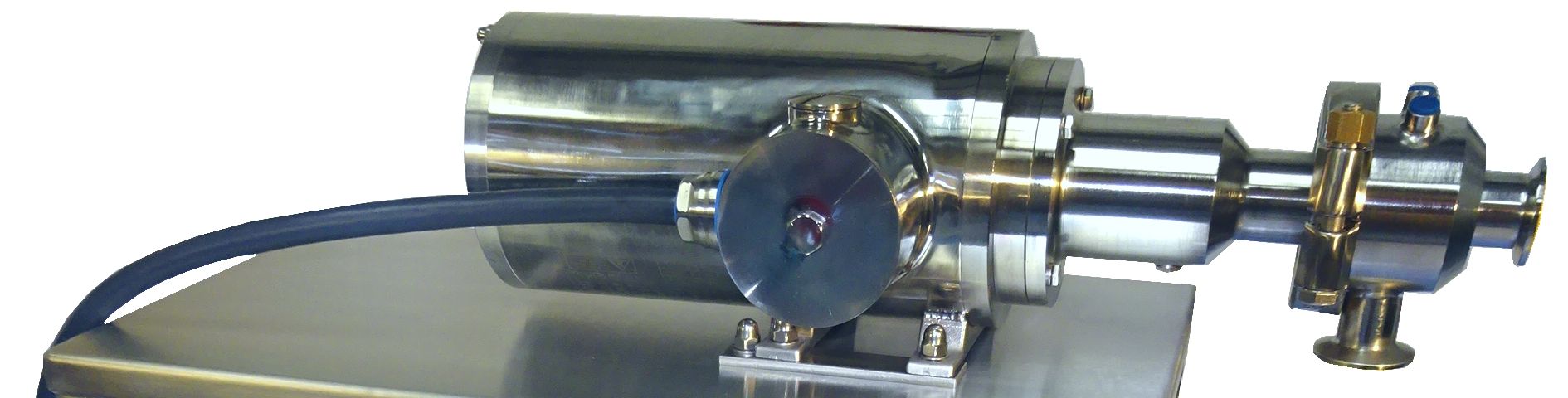

Doses powders directly into high viscosity fluids inline by forming a paste that can be pumped.

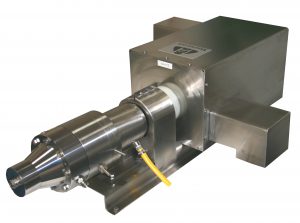

Powder wetting and paste formation

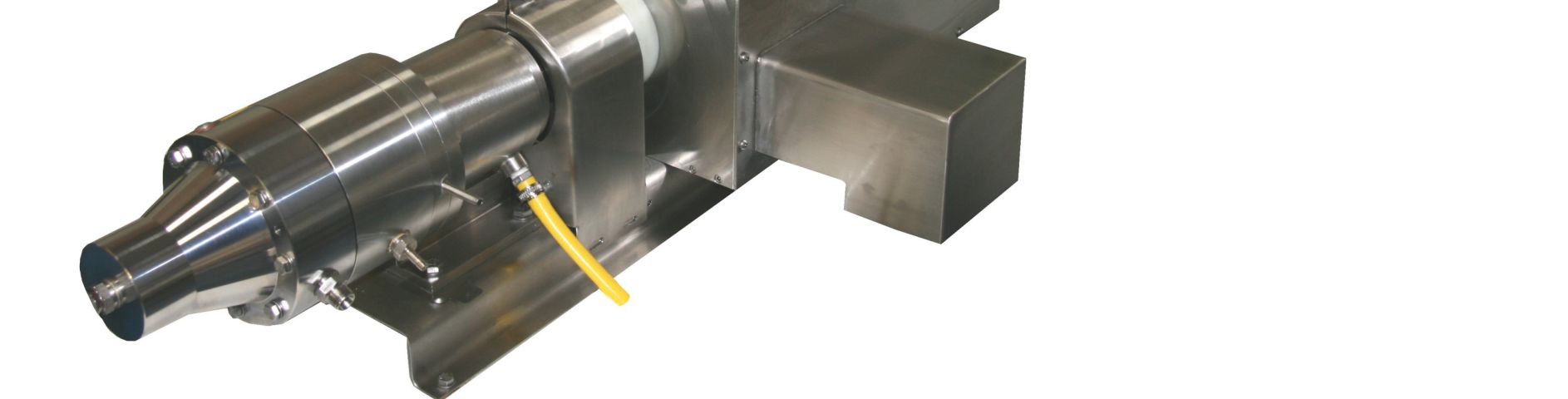

PASTE PUMPING

Allows high pressure pumping of viscous pastes into downstream equipment, including mixers.

Viscous paste pumping

LOW VISCOSITY FLUID MIXING

A comprehensive range of inline fluid mixing equipment to cater for the full scope of viscosity and mixing intensity. From gentle blending actions to sub-micron homogenisation, the Maelstrom mixing range can meet your process demands.

General purpose high shear mixing

High speed for higher performance

High speed + nozzle homogenisation

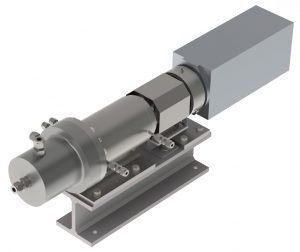

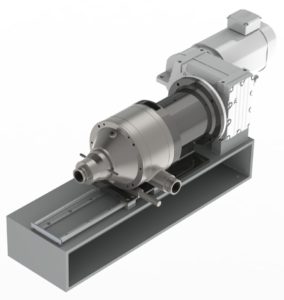

HIGH VISCOSITY FLUID MIXING

A comprehensive range of inline fluid mixing equipment to cater for the full scope of viscosity and mixing intensity. From gentle blending actions to sub-micron homogenisation, the Maelstrom mixing range can meet your process demands.

Gentle blending of shear sensitive materials

Intensive dispersion for viscous fluids

Applications

Inline powder addition and blending

Read application note

Paste mixing and inline viscous blending

Read application note

High shear inline dispersion and de-agglomeration

Read application note

Colour blending into polymer films

Read application note

Emulsions and inline liquid-liquid mixing

Read application note

Pharmaceutical compound formulation

Read application note

Fluid structuring and inline texturing

Read application note

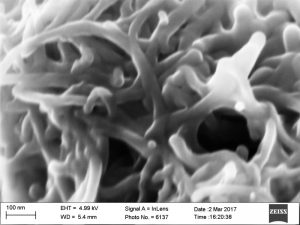

Nano dispersion and de-agglomeration

Read application note

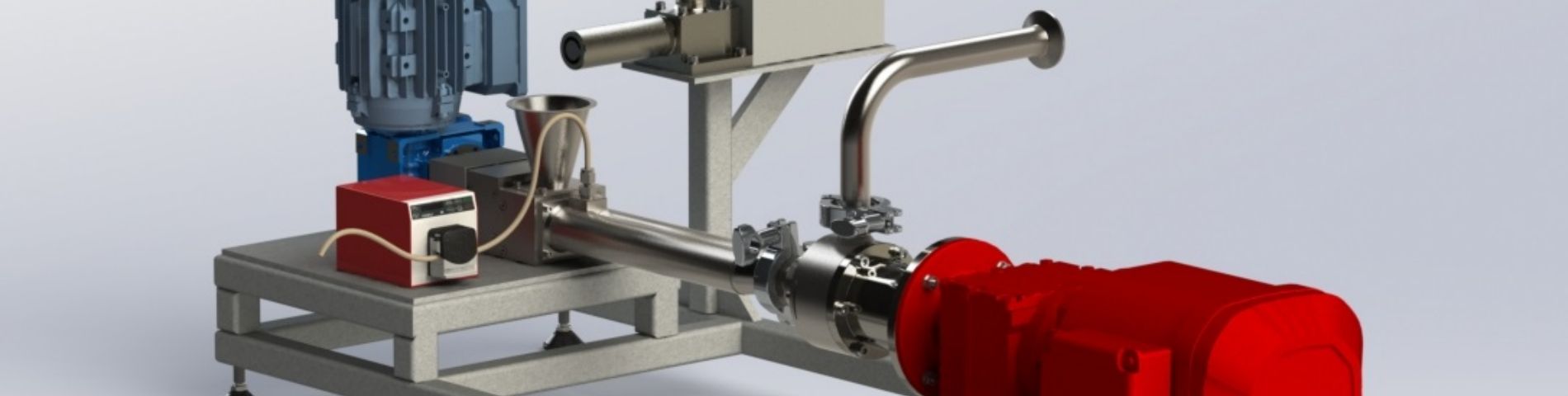

System solutions for complex mixing applications

Read application note

In separating each inline process into its unit operations, the ideal solution for each step can be identified. This is the key to designing successful operations and to converting existing batch processes to inline.

Maelstrom supports unit operations by considering how each machine in its range fits with upstream and downstream equipment for the most efficient process. By integrating its own equipment with third party solutions, Maelstrom can build complete production operations.