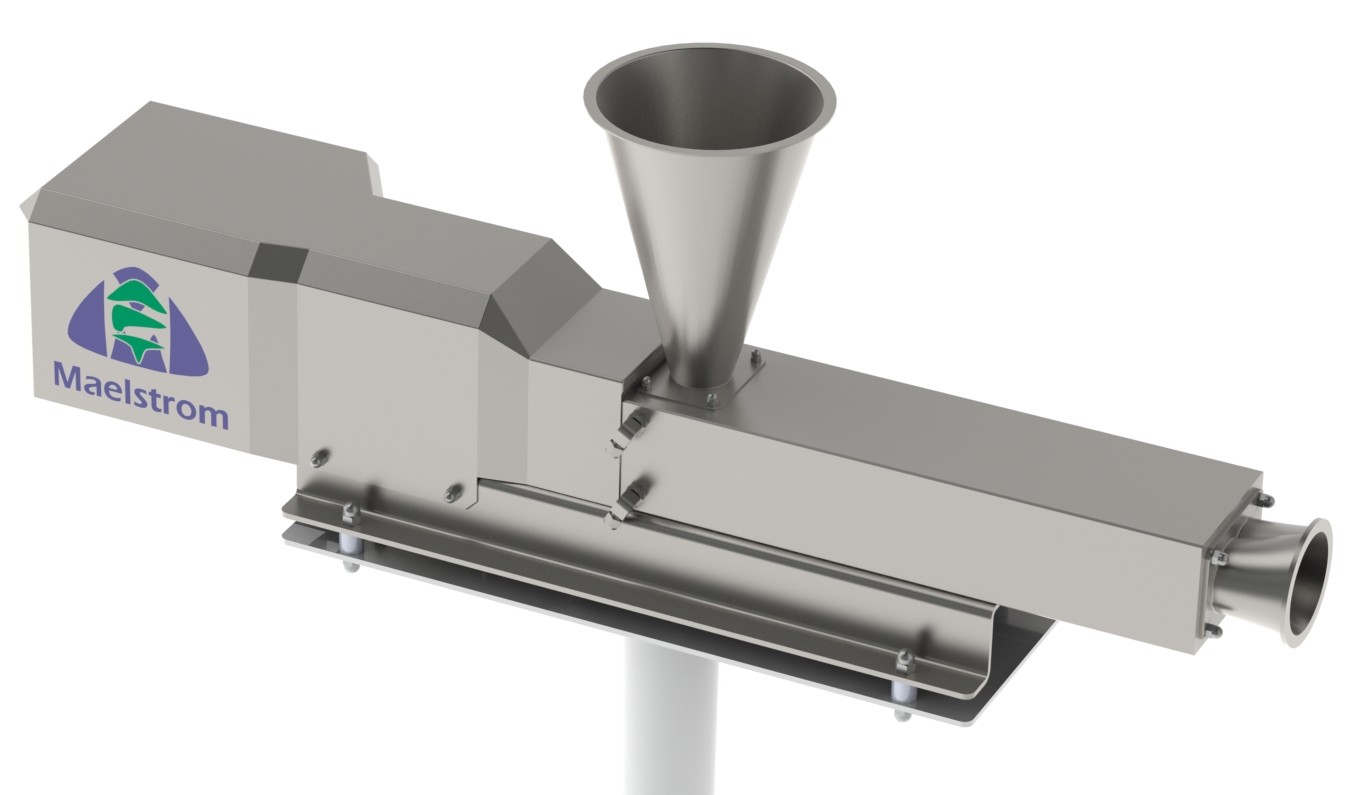

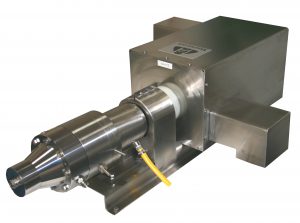

EMT Extruder Mixer - Twin Screw

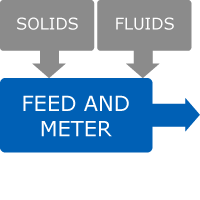

A low-cost alternative to conventional twin screw extruders used for powder inclusion, paste development and high pressure feeding, the EFT uses hygienic, self-wiping, closely-intermeshing, co-rotating screw (COSC) design with optional pressurisation stages for:

- A wide range of applications for powder addition combined with blending and pumping of viscous fluids

- Hygienic applications requiring simple, cleanable geometries with proven hygienic designs

- Shear-sensitive blending of delicate materials

- Addition of difficult, sticky or swelling powders that require self-wiping blending surfaces to avoid clogging

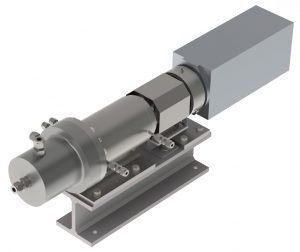

EPS Extruder Pump - Single Screw

A carefully-designed single screw extruder with spiral undercut features in the barrel provides positive feeding action and very high pressure capability for:

- Feeding high viscosity pastes into downstream process equipment at high pressure (e.g. for intensive mixing stages or for filling equipment)

- Extrusion of viscous and visco-elastic materials through dies, pelletizers, etc.

DCL Inline Low Shear Blender/Mixer

Using the principle of inter-cavity transfer to create an intensive blending action with extremely low shear and pressure drop, the DCL is ideal for::

- Effective blending of shear-sensitive liquids with widely-differing viscosities

- Blending of shear-sensitive solids into viscous liquids

- Reacting liquid components with viscous fluids

- Texturing and de-nerving high viscosity fluids and polymers

DCM Inline High Shear Mixer

A robust, general purpose shearing mixer that uses hydraulic action to deliver 20% higher performance than conventional high shear mixers for:

- Fast blending and powder dispersions

- Emulsification and intensive blending at micron scales

- Wide range of models for flowrates from lab-scale to 200 tonnes/hour

- Inline reaction of multiple input streams

- Easy integration into existing processes and plant

DCH Inline Super Speed Shear Mixer

A high performance variant of the DC mixer range running at speeds of up to 60,000 rpm to deliver sub-micron dispersing, deagglomeration and emulsification:

- Very fine powder dispersion and deagglomeration

- Emulsification, reacting and intensive blending at sub-micron scales

- Jacket option for product cooling

- High speed machine tool spindle drives for precision and reliability

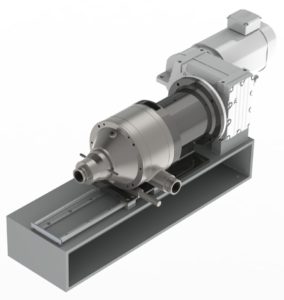

UML Ultra Mixer - Low Speed

Combining the actions of inter-cavity transfer, extrusion and extensional stressing through internal nozzle stages, the UML provides adjustable, highly intensive stressing of viscous materials for:

- Effective dispersion of solids into highly viscous fluids

- Multi-stage compounding and reacting of polymers and similar fluids

- Texturing, structuring and conditioning of viscous fluids

UMH Ultra Mixer - High Speed

Extremely intensive rotational shear and extensional stress at very high rotational speeds in low to medium viscosity fluids for:

- Micro- and nano-particle dispersion

- Sub-micron emulsification

- High energy blending of multiple input streams

- Dilution of concentrates at high flowrates