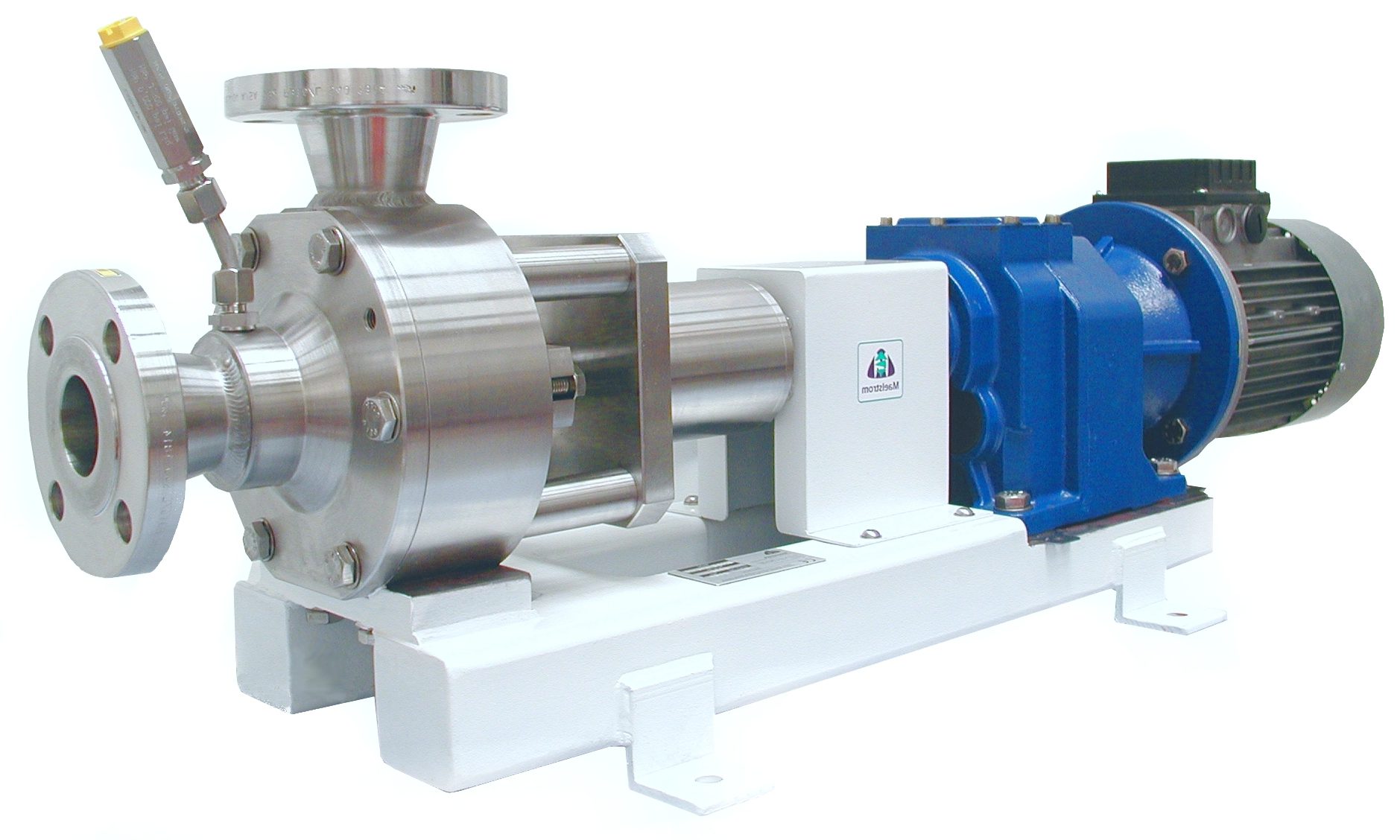

DCL inline

low shear mixer

Key Features

DCL inline low shear mixer

Key Features

With the same internal geometry as the DCM range of high shear mixers, the DCL is run at lower speeds on viscous fluids as a low-shear inline blender. The inter-cavity transfer action of the rotor and stator provide a gentle cutting and folding action at low speeds and this is ideal for mixing shear-sensitive materials. Running at low speeds and with relatively large rotor-stator gaps, the DCL is a tough and reliable workhorse that has been used in many industries around the world for almost 20 years. Available with flameproof and hygienic design options, the DCL covers a very wide range of applications.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.

The rotor and stator of the DCL carry multiple rows of mixing cavities to provide the inter-cavity transfer effect as fluid passes through the mixer. There is no possibility of short-circuiting the mixing action, so all of the fluid is processed uniformly and temperatures are kept tightly controlled by heat transfer fluid inside the stator jacket and rotor cavity.

The patented FDM geometry underlying the DCL covers a very broad range of applications and viscosities. The geometry can also be varied for special applications with Maelstrom's custom design service.

For inline blending of shear-sensitive, viscous fluids, pastes and polymer streams, the DCL rotor-stator mixer offers unbeatable performance. Based on inter-cavity transfer principles DCL machines provide ultra-low shear mixing at low speeds and with very low pressure drops. The ability to incorporate multiple inlet streams and mix widely differing viscosities means that DCL replaces static mixers, pin mixers, kneaders and z-blade blenders in many applications where higher performance is needed.

DCL25

Max. flow at 1,000,000 cP

25 kg/hr

Max speed: 400 rpm

Motor power: 0.25kW

Max pressure: 200 barg

DCL50

Max. flow at 1,000,000 cP

100 kg/hr

Max speed: 200 rpm

Motor power: 0.75kW

Max pressure: 200 barg

DCL75

Max. flow at 1,000,000 cP

250 kg/hr

Max speed: 140 rpm

Motor power: 1.5kW

Max pressure: 200 barg

DCL100

Max. flow at 1,000,000 cP

400 kg/hr

Max speed: 100 rpm

Motor power: 2.2kW

Max pressure: 200 barg

DCL150

Max. flow at 1,000,000 cP

900 kg/hr

Max speed: 70 rpm

Motor power: 4kW

Max pressure: 200 barg

DCL200

Max. flow at 1,000,000 cP

1600 kg/hr

Max speed: 50 rpm

Motor power: 7.5kW

Max pressure: 200 barg

DCL250

Max. flow at 1,000,000 cP

3000 kg/hr

Max speed: 40 rpm

Motor power: 15kW

Max pressure: 200 barg

DCL300

Max. flow at 1,000,000 cP

4400 kg/hr

Max speed: 35 rpm

Motor power: 18.5kW

Max pressure: 200 barg

DCL350

Max. flow at 1,000,000 cP

6000 kg/hr

Max speed: 30 rpm

Motor power: 30kW

Max pressure: 200 barg

DCL400

Max. flow at 1,000,000 cP

7500 kg/hr

Max speed: 30 rpm

Motor power: 45kW

Max pressure: 200 barg

DCL500

Max. flow at 1,000,000 cP

12000 kg/hr

Max speed: 20 rpm

Motor power: 45kW

Max pressure: 200 barg