Nano & custom

mixers for special applications

Development examples

Nano & custom

mixers for special applications

Development examples

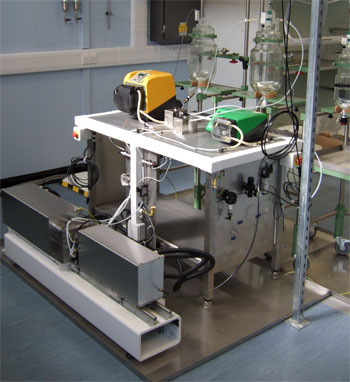

Since 1998, Maelstrom has been at the forefront of innovation in fluid mixer design and has built a strong range of technologies that underpin its machine range. Being an innovative company, customers often approach us to develop special-purpose machines or equipment for applications that present particular challenges.

Maelstrom continues to offer this custom design and bespoke innovation service, especially in the field of nano processing, where customers often face uniquely difficult problems in scale-up to production flowrates.

An ongoing involvement in research projects at UK and European level and close collaboration with UK universities reinforces Maelstrom's strategy of always being able to offer its customers the latest and best technology that is suited to their purpose.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.