Application example:

Emulsions

and liquid-liquid mixing

Problem:

How can I mix sub-micron emulsions and other liquid-liquid systems inline at high flowrates?

Solution:

The Maelstrom UMH inline ultra mixer

Application example:

Emulsions

and liquid-liquid mixing

Problem:

How can I mix sub-micron emulsions and other liquid-liquid systems inline at high flowrates?

Solution:

The Maelstrom UMH inline ultra mixer

As emulsions are inherently unstable oil-water systems, a combination of small droplet size and chemical action is needed to make them into useful, stable fluids. Reducing droplet size requires intensive mixing action and droplet mean diameter can be correlated to mixing energy and power. To emulsify to sub-micron sizes, the mixing energy required is very large and few technologies are able to provide the necessary performance. Even fewer can deliver this performance at industrial scales, so the problem is finding a scalable, high performance inline solution for sub-micron emulsification.

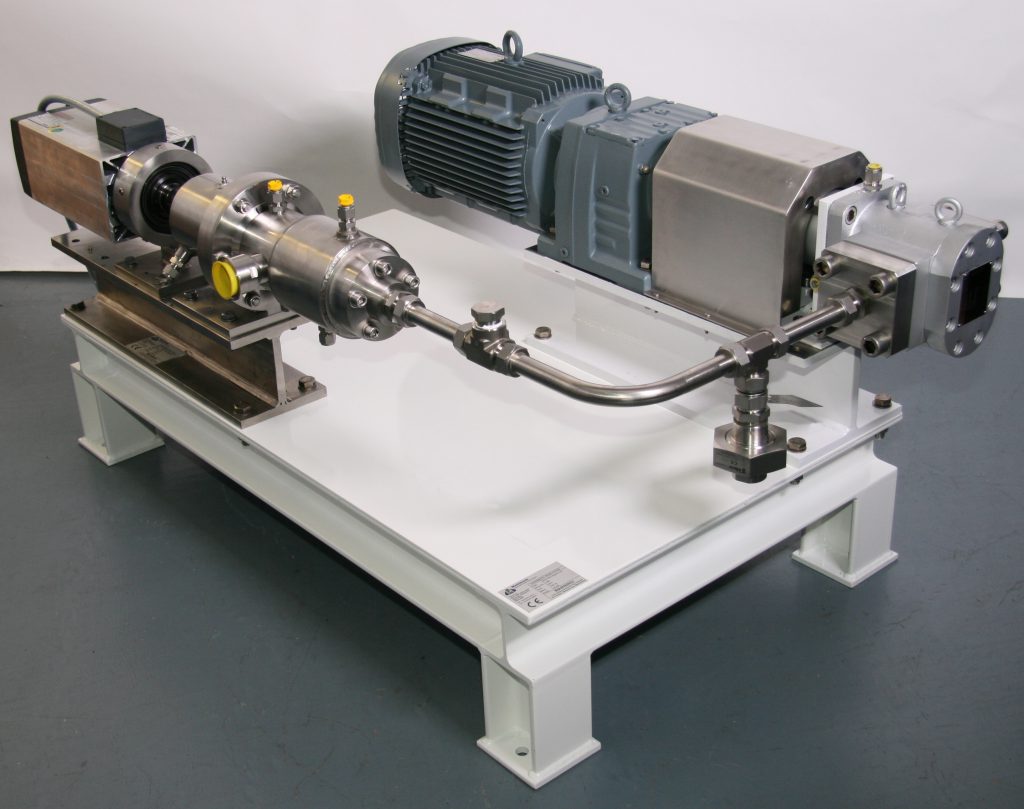

The UMH inline mixer from Maelstrom provides extreme levels of shear and specific energy to give sub-micron emulsions and other liquid-liquid mixtures. Fed by a high pressure pump, the UMH can process a coarse pre-blend of the ingredients or one of the phases can be fed directly into the mixing head via a separate pumped stream.

With shear rates of 108 s-1 possible at speeds up to 60,000 rpm (UMH25), the UMH can deliver consistent performance in a factory setting. Flowrates of tonnes/hour are typical in food, paints, coatings and many other application areas. Precision machine tool spindle drives with air or liquid cooling are fitted to ensure reliable operation and minimal maintenance and a wide range of hygienic and hazardous area options are available.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.