The classic chocolate conching process developed in the 19th century has changed little in the last hundred years and is still a lengthy batch process. To improve the flavour and rheology of chocolate prior to moulding or coating processes, conching mixes it using z-blade or sigma-blade type machines for several hours. This reduces the viscosity of the chocolate, changes the sugar crystal morphology and drives off certain undesirable volatile compounds.

This process has proved to be notoriously difficult to convert to an inline operation to obtain the benefits of process intensification such as cost reduction and efficiency and throughput improvements. This is due to the particular characteristics of chocolate which behaves as a shear-sensitive fluid when stressed in certain ways. The question is: can an inline system for chocolate production be developed to revolutionise the way it is made?

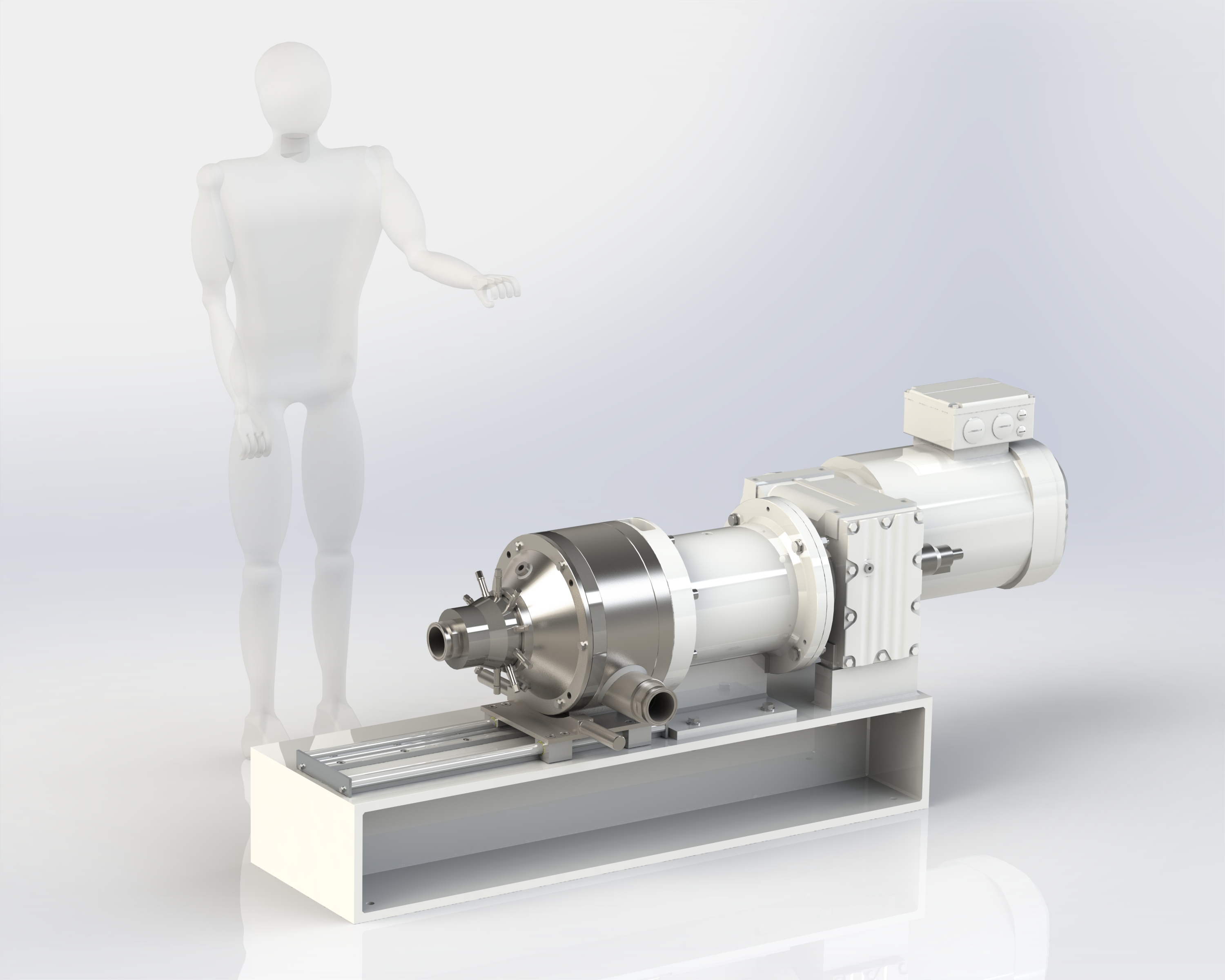

By taking a ground-up approach to this problem, Maelstrom has developed a system solution using a combination of EMT, UML and DCL mixers. The basis of the concept is to keep the viscosity of the incoming chocolate as high as possible so that a high amount of stress can be applied. This raises the additional difficulty of preparing and feeding such as paste into the UML from the powder (or crumb/flake) and liquid fat ingredients. The EMT is the ideal solution to this, with its ability to blend and dose metered ingredient streams at very high viscosity. A specially-developed UML mixer then applies the majority of the stress and a DCL is used to blend in any remaining liquid fats to make up the final recipe.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.