EMT - Twin-screw extruder mixer for controlled inline addition of solids to liquids

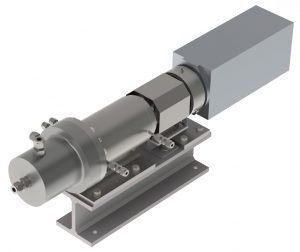

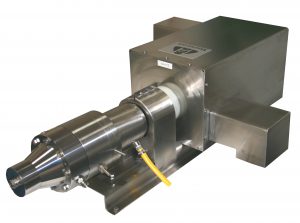

EPS - Extruder pump, single screw, for pressurising pastes polymers and doughs up to 200 bar

DCL - Inline low shear blender for mixing shear-sensitive fluids under tight temperature control

DCM - Inline high shear mixer for general dispersion and emulsion duties

DCH - Inline super-speed high shear mixer for sub-micron dispersions and emulsions

UML - Inline low speed ultramixer for extreme stressing of high viscosity fluids to disperse, deagglomerate and react

UMH - Inline high speed ultramixer for extreme low viscosity mixing to disperse, emulsify and react at nano scales