Application example:

Nano dispersions

and inline de-agglomeration

Problem:

How can I disperse and de-agglomerate nano-scale powders in low to medium viscosity liquids at production flowrates?

Solution:

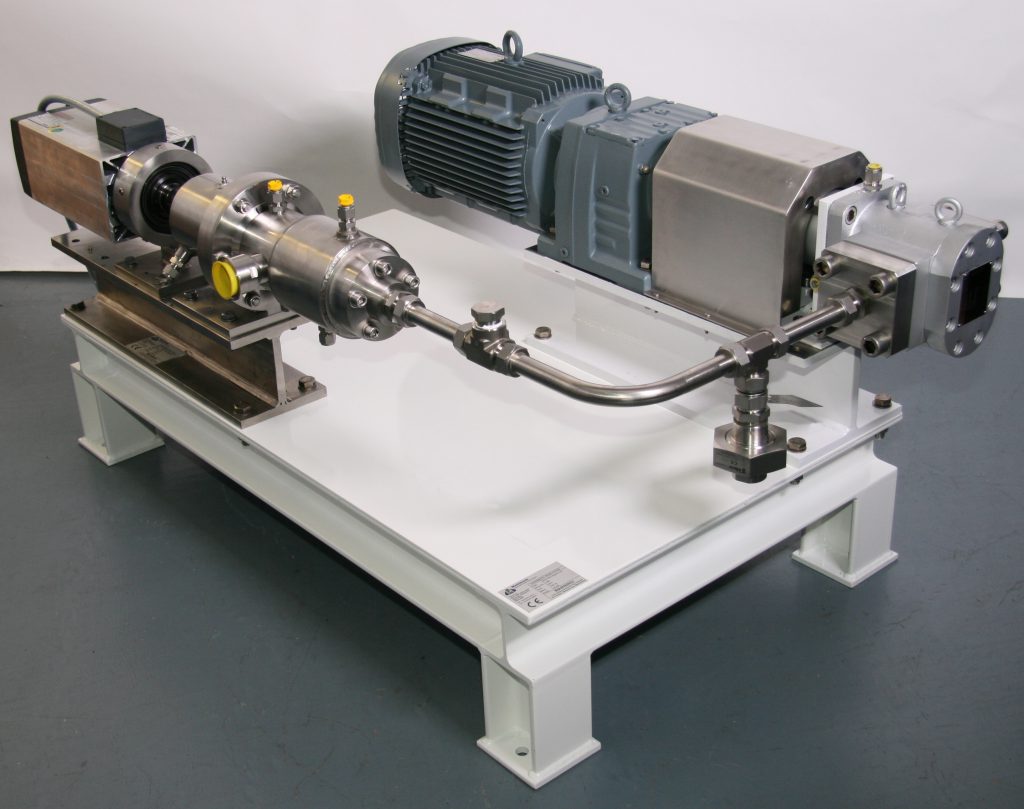

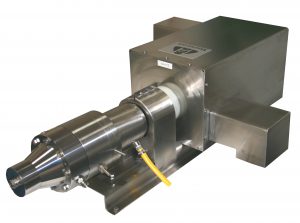

The Maelstrom UMH inline ultra mixer with high pressure feed pump - a high throughput alternative to ultrasonic mixers and media mills for deagglomerating nano materials.

Application example:

Nano dispersions

and inline deagglomeration

Problem:

How can I disperse and de-agglomerate nano-scale powders in low to medium viscosity liquids at production flowrates?

Solution:

The Maelstrom UMH inline ultra mixer with high pressure feed pump - a high throughput alternative to ultrasonic mixers and media mills for deagglomerating nano materials.

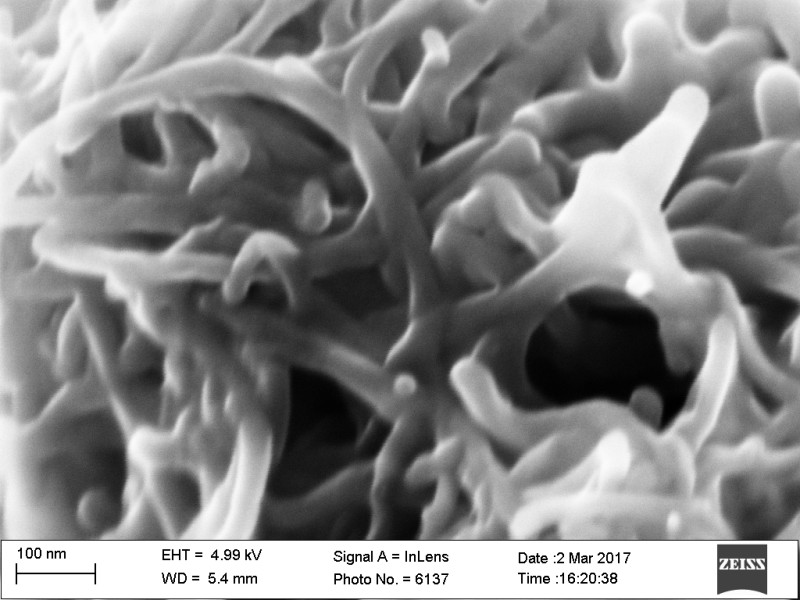

Nano particles are increasingly important in formulations in a wide range of commercial products. Whilst techniques to manufacture organic and inorganic particles with particular characteristics have advanced greatly, these particles usually need to be dispersed into some form of fluid for their practical application. The small size of the particles (less than 100nm in at least one dimension) means that their inter-particulate attractive forces are very strong and they form clumps or agglomerates when suspended in a fluid.

Both surface chemistry and a very high degree of mixing energy is required to agglomerate them so that they exhibit their nano-scale properties rather than remaining as micro-scale lumps. Whilst sonication, media milling and ultra-high pressure homogenisation can do this quite effectively at lab scales, the problem is that these do not easily scale to production volumes. This is a potential roadblock to wide-scale adoption and use of nano-enabled materials.

With its very high rotational speeds and internal nozzle geometry, the UMH inline rotor-stator mixer from Maelstrom offers extreme levels of shear and specific energy at high flowrates. The energy and power levels rival those of ultrasonic and cavitation-based mixers to deliver the necessary de-agglomeration action for organic and inorganic dispersions. Trials on carbon nanotubes, graphene, copper oxide and other materials in various research programmes have verified the technology behind the UMH and led to the development of the production-grade range of machines that is now offered by Maelstrom.

Coupled to a high pressure feed pump, the UMH can process a wetted nano-particle slurry at 1-5% typical concentrations into a smooth, de-agglomerated fluid. The drastically increased surface area of the particles means that the fluid often exits the machine as a paste, which helps to maintain stability. This can be treated as a masterbatch for later dilution to final concentrations. Precision machine tool spindle drives with air or liquid cooling are fitted to ensure reliable operation and minimal maintenance and a wide range of hygienic and hazardous area options are available.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.