Application example:

Fluid structuring

and inline texturing

Problem:

How can I improve fluid structure and texture during phase changes in edible fats and similar applications, when processing inline?

Solution:

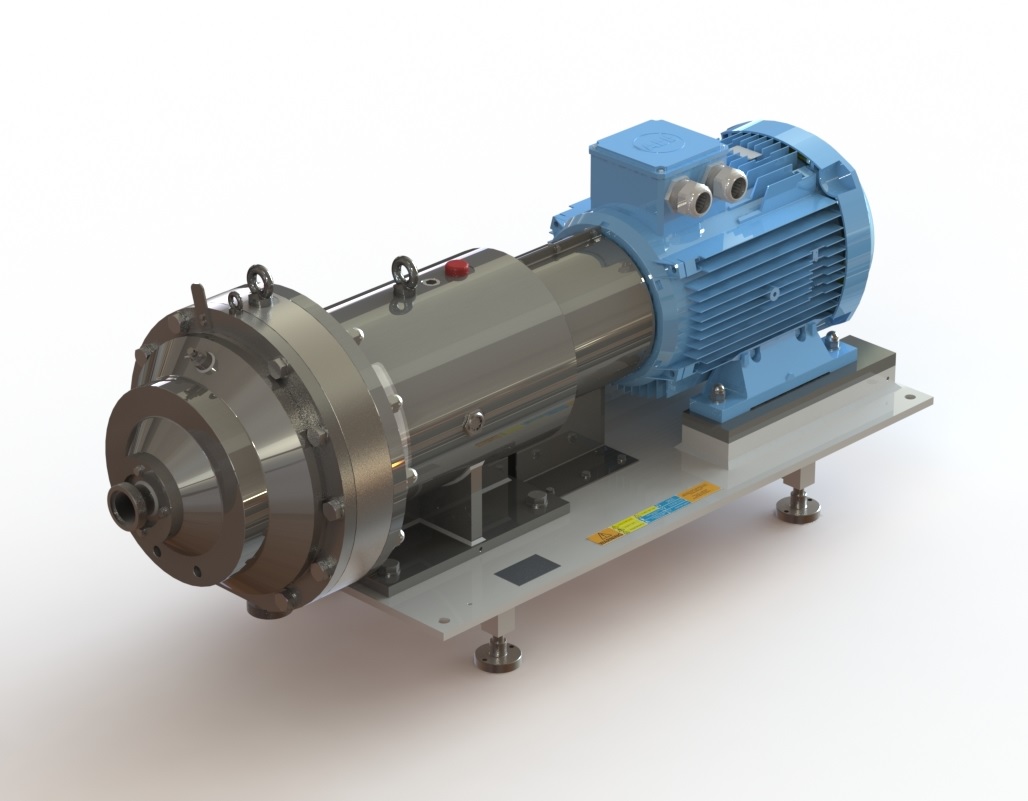

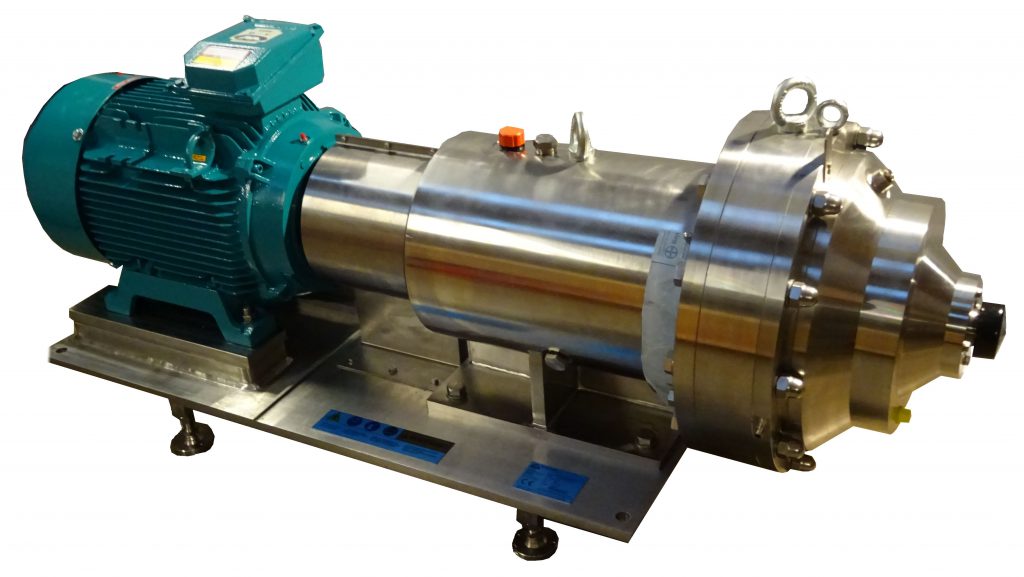

Maelstrom's DCL inline mixer can replace pin mixers and kneaders in structuring and texturing applications including margarine, ice cream and similar applications, providing:

Application example:

Fluid structuring

and inline texturing

Problem:

How can I improve fluid structure and texture during phase changes in edible fats and similar applications, when processing inline?

Solution:

Maelstrom's DCL inline mixer can replace pin mixers and kneaders in structuring and texturing applications including margarine, ice cream and similar applications, providing:

Many fluids undergo phase changes during processing and need remedial treatment to improve their structure or texture. Examples are found in edible fats such as margarine and ice-cream where crystal formation on cooling can lead to the product having an undesirable, fatty mouth feel unless it is "whisked" or "whipped" in a pin mixer. The structuring action breaks up large crystals to make the product smoother and softer; properties that consumers value.

Although pin mixers and similar kneading devices provide the structuring action, they are not efficient and much of the material can pass through the machine without being treated. A more consistent result with lower energy costs is needed.

With its multi-stage inter-cavity transfer action, the Maelstrom DCL mixer can provide homogeneous structuring and blending with no bypass for the process fluid. This means that all of the fluid sees the stressing zones and is treated in the same way, resulting in more uniform, consistent results and higher perceived product quality.

For food and pharmaceutical applications, the DCL has range of hygienic options to meet the requirements of EHEDG, 3A and cGMP. Single and double mechanical seals can be specified and both the rotor and stator can be heated or cooled to suit the needs of the product.

Want to know more?

Contact us today to discuss your application or to book a free demo or trial.